Induction Hardening

Agni Induction Technology has a rich experience on induction hardening with different kinds of shafts, Gears, various types of geometry components. Induction Hardening Process needs to concentrate some parameters after the power and frequency selection

- Heating Method

- Inductor Selection

- Quenching methods

1. Heating Method

Heating methods will vary depending upon your component and requirement of induction hardening. A special type of mechanism needs to achieve the desired induction hardening properties. Usually following heating methods will choose.

- Single Shot Hardening

- Scan Hardening

2. Inductor Selection

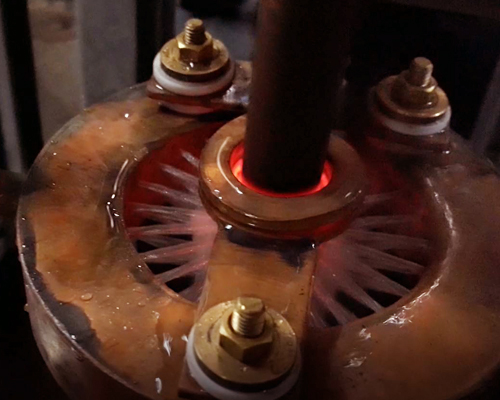

Inductor profile geometry is one of the factors which greatly influenced induction heating. Air gap between the component and inductor is related to electromagnetic force which induces the Eddy current on the component. Agni Induction Technologies has good knowledge on eddy current and its flowing path. Our engineers faced lots of practical problems and provided solutions on inductors.

3. Quenching Methods

In Induction hardening process, quenching is a very important thing to harden the material. Different types of quench depending upon your material and metallurgical properties. Quenching will affect the physical properties of the material. Agni Induction Technologies has excellent knowledge on quenching. We will choose the best method of quench.